Cement Industries

Powering Cement Industry Efficiency

Cement manufacturing is a power-intensive and continuous operation that relies on heavy-duty electrical equipment such as motors, transformers, and generators. Any electrical failure can lead to production downtime, increased maintenance costs, and significant financial losses.

Working process

Here is How It Works

At Gopal Electrical, we follow a structured process to deliver precision rewinding and repair services for AC/DC motors, generators, transformers, and electromagnets.

Inspection & Diagnosis

Detailed analysis of motors, generators, transformers,

and electromagnets to identify faults.

Rewinding & Repair

Repair/replacement of bearings, brushes, insulation, and other components.

Testing & Assurance

Rigorous voltage, load, insulation, and performance tests

Reassembly & Delivery

Final inspection and reassembly for optimal performance

Why Does the Cement Industry Need These Services

Motor Rewinding & Repair

In cement manufacturing, crushers, rotary kilns, and conveyor belt motors are the backbone of production. These motors power crushing units that break down raw materials, rotary kilns that heat materials at extreme temperatures, and conveyor belts that transport materials across different stages of processing

Why is it Needed ?

- Cement plants use high-power AC/DC motors to run crushers, kilns, and conveyor systems.

- Continuous operation leads to wear and tear, overheating, and insulation breakdown.

- Faulty motors can reduce production speed, increase power consumption, and cause sudden breakdowns.

How It Helps ?

- Rewinding restores motor efficiency, ensuring smooth operation.

- Prevents overheating and short circuits, extending motor lifespan.

- Enhances energy efficiency, reducing electricity costs.

Why Does the Cement Industry Need These Services

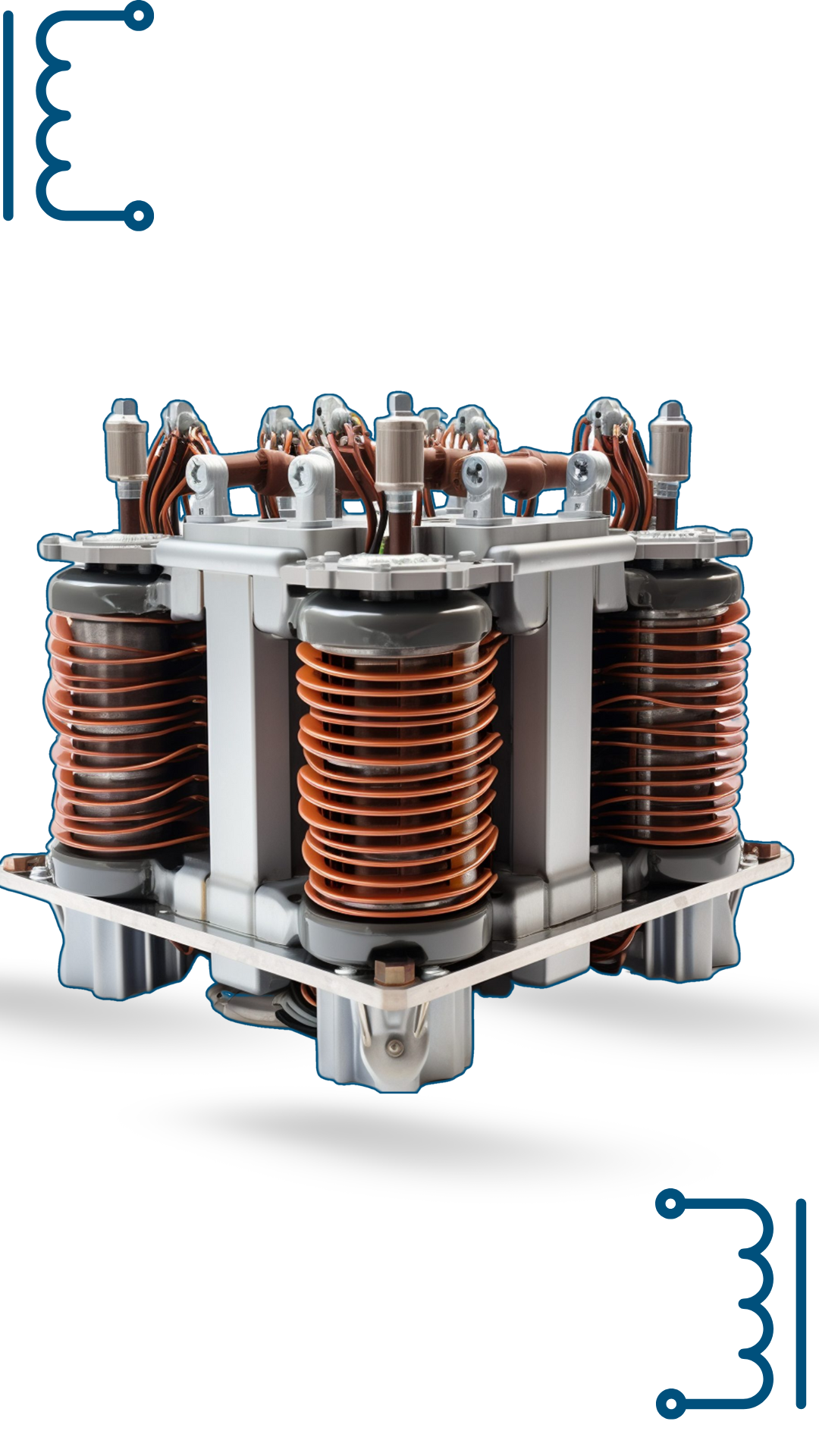

Transformer Maintenance

In cement manufacturing, grinding and blending units process raw materials into fine cement powder. These units require a stable power supply to run grinding mills, mixers, and blending machines efficiently. Power disruptions can cause production delays, material wastage, and higher operational costs.

Why is it Needed ?

- Transformers regulate power supply to different units like grinding mills, blending stations, and raw material crushers.

- Dust, heat, and constant high loads can lead to insulation degradation, overheating, and reduced efficiency.

- A failing transformer can cause voltage drops, power surges, and even complete plant shutdowns.

How It Helps ?

- Regular servicing prevents breakdowns, ensuring an uninterrupted power supply.

- Improves voltage stability, protecting sensitive equipment from fluctuations.

- Enhances efficiency, reducing power losses and ensuring smooth plant operations.

Why Does the Cement Industry Need These Services

Generator Overhauling

Cement manufacturing is a high-power process where power failures can disrupt production and cause losses. Backup generators keep crushers, kilns, and mills running, but over time, they wear out, leading to inefficiency, higher fuel use, and breakdowns.

Why is it Needed ?

- Cement plants cannot afford power outages—a sudden blackout can halt kilns, crushers, and conveyors, leading to massive losses.

- Generators act as a critical backup, ensuring operations continue smoothly.

- Over time, generators experience coil degradation, insulation breakdown, and reduced power output.

How It Helps ?

- Restores power output, ensuring reliable backup energy.

- Prevents emergency failures, reducing unexpected downtimes.

- Optimizes fuel efficiency, lowering operational costs.

A Must-Have for Cement Plants

Cement manufacturers rely on heavy-duty electrical systems to keep production running smoothly. However, motor failures, transformer issues, and generator breakdowns can lead to costly downtimes, reduced efficiency, and increased operational expenses

Enhance Equipment Efficiency

Keep motors, transformers, and generators operating at peak performance.

Reduce Operational Costs

Prevent unexpected failures, lower maintenance expenses, and improve energy efficiency.

Ensure Continuous Production

Avoid costly downtimes and power disruptions

Get in Touch with Us!

At Gopal Electrical, we ensure efficient motor, transformer, and generator services for minimal downtime and reliable operations.

Call Now